因为不是所有的沥青都是一样的, engineers need to predict how well an asphalt mixture will perform in addition to the maximum load it can support. 虽然有很多方法可以确定, the Marshall test is one of the most common methods in dictating the best proportion of aggregate and binder materials for a mixed design. 通过测量沥青试样的多种品质, it progressively narrows in on an optimum asphalt mix design for a specific application.

The Marshall method is a holistic approach to asphalt pavement mix design. 通过一系列的步骤, it is able to establish the ideal asphalt content for a mix that will provide maximum strength and stability for its load. 通过马歇尔测试,工程师能够:

- 选择矿物骨料和粘结剂材料

- Measure the strength and flow of materials through load testing

- 在实验室环境中测试材料的性能

The Marshall Stability Method was first discovered in 1939 by Bruce Marshall at the Mississippi Highway Department. Due to its simplicity as well as its rapid and effective test results, 该方法后来被美国政府采用.S. Army Corps of Engineers to evaluate asphalt mix designs for World War II airfields. The large military aircrafts required a landing strip able to withstand their extremely heavy loads, 这是马歇尔测试可以保证的. Its popularity spread to many state transportation departments and soon the Marshall test became the most widely used pavement design system in the world.

样品制备

The Marshall method uses several trial aggregate-asphalt binder blends each with a different asphalt binder content. By evaluating each trial blend’s performance, an optimum asphalt binder content can be selected.

如何进行马歇尔测试

步骤1:选择正确的聚合

沥青 is composed of a mix of aggregates and bitumen to bind them together. 因为不同的沥青有不同的用途, it is important to choose the right aggregate for the job. 选择聚合, 物理特性,如电阻, 颗粒形状, 耐久性和吸收性必须仔细测试. 另外, using more than one type of aggregate for better results requires mix testing during this process. This crucial step ensures strength and stability for the final asphalt mix.

第二步:选择正确的沥青粘合剂

While the Marshall test has no process for testing binders, 这是制造沥青混合料的关键步骤. 而粘结剂可根据经验选择, 最常见的, engineers will refer to the Superpave binder system to test the relationship between expected climate conditions and viscosity. This will help to determine which asphalt binder to include in the mix.

步骤3:准备样品

In order to choose the best bitumen-aggregate blend for a specific project, many mixtures with varying levels of binder content are tested. 最常见的, 15 samples (five bitumen-aggregate blends with three different levels of binders) are used to determine the optimal asphalt binder content for the application. 为进一步的测试做准备, the 15 samples are heated to the same specific temperature using a lab oven.

步骤4:样品压实

一旦准备好并加热, a Marshall compactor is used to compress the samples with a 10lb steady pressure following ASTM D6926 监管标准. The samples are then put into compaction molds of 4” or 6” diameters. Once compacted, the specimens are extracted from the mold using a sample ejector.

步骤5:稳定性和流量测试

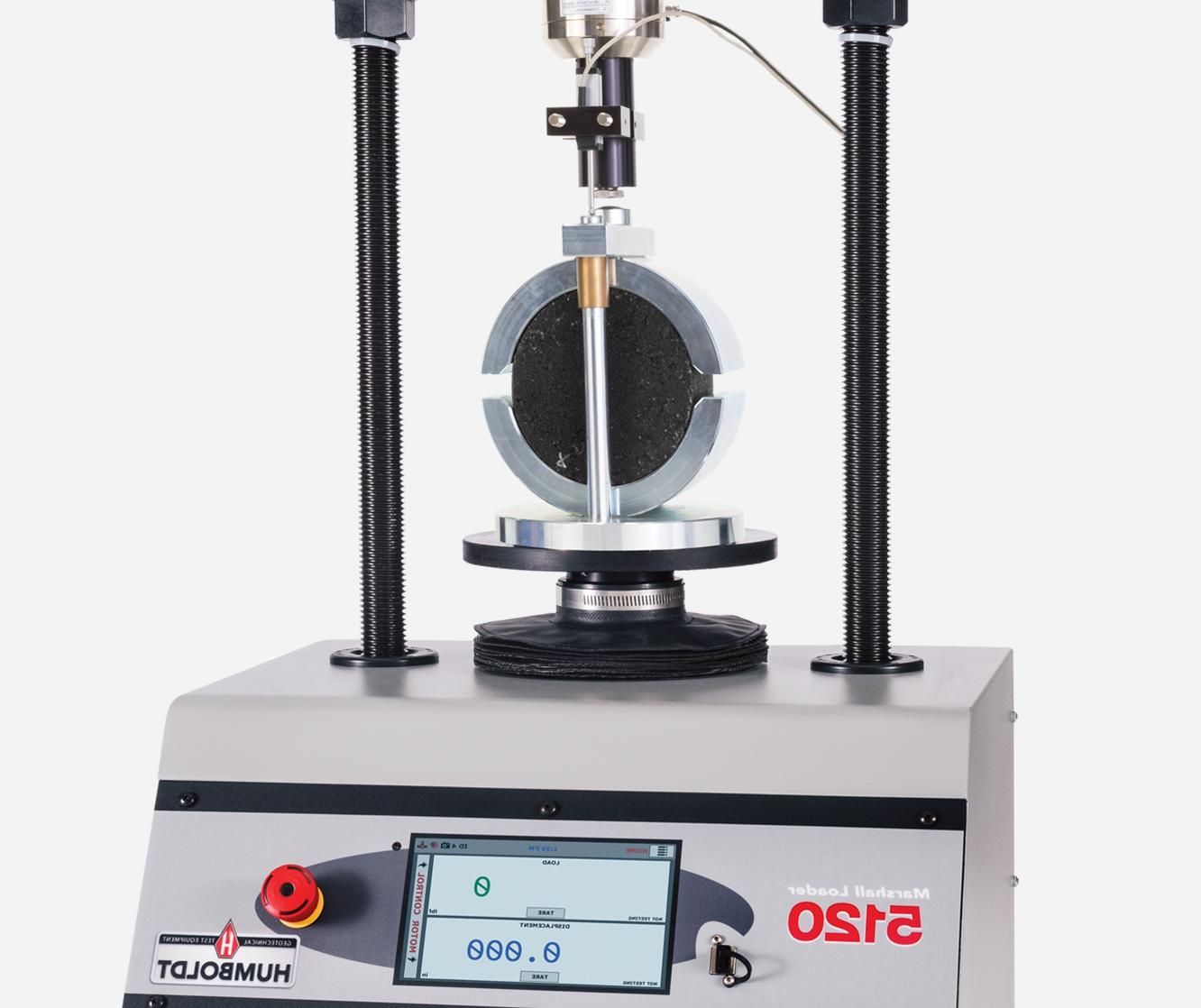

The next step of the Marshall test is to examine a mix’s stability and flow. The compacted specimens are put into a water bath before being placed into a Marshall breaking head. 然后对它们进行以下测试 ASTM D6927 criteria to measure the maximum load a particular blend will be able to support using a Marshall load frame. 以每分钟2英寸的速度加载, a sample’s stability is measured as the maximum load it can reach.

During the 加载 process, a specimen’s plastic flow, also called deformation, is recorded in 0.01英寸的增量使用刻度表. Additional accessories to support the load frame during this step are also available. 使测试更快,更有效, 洪堡 provides NEXT software that seamlessly connects your equipment to a digital platform. This software is able to record, graph, calculate and report Marshall test values automatically.

第六步:分析密度和空气空隙

The final step in the Marshall test is to assess the specific gravity and presence of air voids of an asphalt mixture. These tests ensure that the blend meets local and state standards and prevent issues in the future. 比重和密度是用 ASTM D2041(稻米试验) for loose material and ASTM D2726 for compacted specimen. Air void content on the other hand is tested using ASTM D3203.

Once finished, the Marshall test produces an asphalt mix specific for its intended use. Simple, fast and easy to do, it’s still one of the most popular asphalt tests today. 洪堡 supplies the highest-grade Marshall test equipment in many varieties.

If you have questions or need help selecting equipment, please call us at 1.800.544.7220或使用我们的 问洪堡 form.